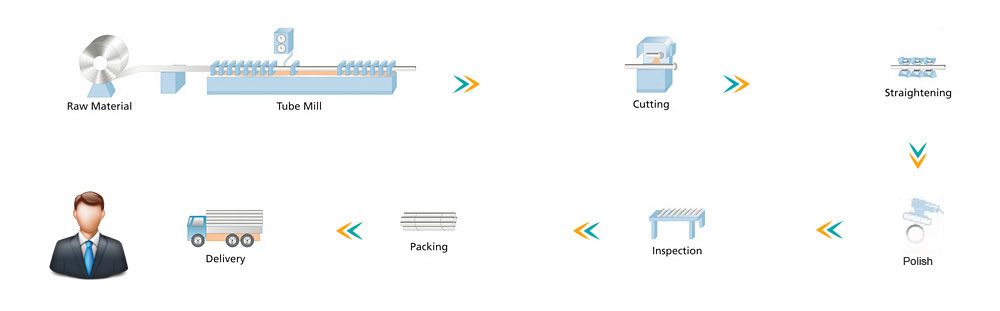

Process Chart

Vikas stainless manufacturing of stainless steel welded tubes is carried out on custom designed, sophisticated tube mills where stainless steel strips, slit to precise widths, are continuously formed into a tubular shape and welded by Tungsten - Inert - Gas(TIG) welding. The welding is highly precise and completely automated. The edges of the strips are heated and fused together under protective atmosphere of argon through a non-conrsumable electrode without the addition of any filler metal. The integrity of the weld is continuously controlled by sophisticated electronics devices that maintainds perfact, arc stability, and direction in a magntic field.